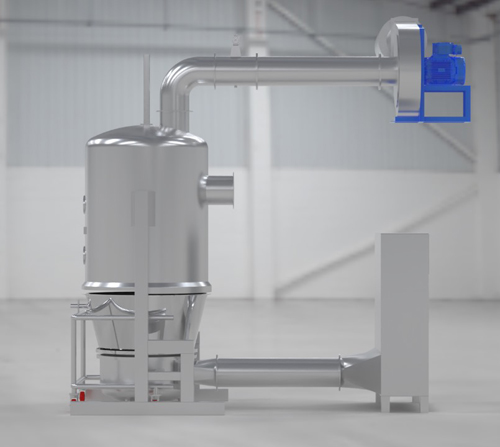

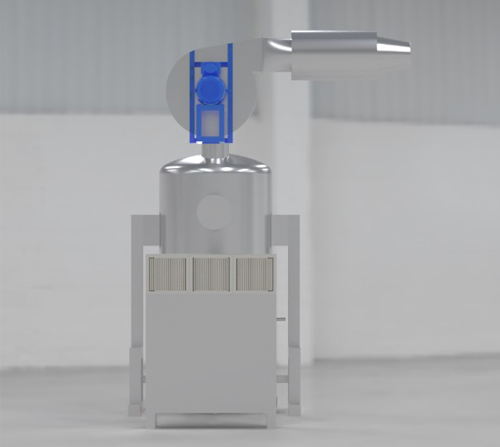

Fluid Bed Dryer

A fluid bed dryer is a type of industrial equipment used for the drying of granular and powdered materials. It operates on the principle of fluidization, where air or gas is passed through a perforated plate, causing the particles to behave like a fluid. This fluidization enhances the heat and mass transfer, leading to efficient drying. Fluid bed dryers are commonly used in the pharmaceutical, food, chemical, and other process industries. Here's an overview of the key features and applications of fluid bed dryer machines:

Basic Components:

- • Bed: The bed consists of solid particles (usually the material being dried) that are supported on a mesh or perforated plate.

- • Air Distribution System: Air or gas is introduced from the bottom through the perforated plate to fluidize the bed.

- • Heating System: Heat is supplied to the fluidizing air, which then transfers the heat to the wet material for drying.

Principle of Operation:

- • The wet material is placed on the fluidized bed.

- • Air or gas is blown through the bed from underneath, causing the particles to become suspended and behave like a fluid.

- • Heating System: Heat is supplied to the fluidizing air, which then transfers the heat to the wet material for drying.

- • This fluidization enhances heat and mass transfer between the drying medium and the material.

Uniform Drying:

- • The fluidization process ensures uniform drying of each particle, eliminating issues such as overheating or under-drying.

Controlled Temperature and Residence Time:

- • The fluid bed dryer allows precise control over temperature and residence time, providing flexibility in the drying process.

Applications:

- • Pharmaceuticals: Drying of pharmaceutical powders, granules, and particles.

- • Food Industry: Drying of food ingredients, such as grains, cereals, and powdered products.

- • Chemical Industry: Drying of various chemical substances and intermediates.

- • Minerals and Mining: Drying of minerals and ores.

Advantages:

- • Rapid Drying: The fluid bed dryer can achieve rapid and uniform drying due to efficient heat transfer.

- • Gentle Handling: The fluidization process minimizes the risk of particle attrition or degradation.

- • Versatility: Suitable for a wide range of materials, including heat-sensitive products.

Batch and Continuous Operations:

- • Fluid bed dryers are available in both batch and continuous configurations to meet different production requirements.

Top Spray Granulation:

- • Some fluid bed dryers are equipped for additional processes, such as top spray granulation, where granules are formed during the drying process.

CIP (Clean-in-Place) Systems:

- • Many modern fluid bed dryers are designed with Clean-in-Place systems, making cleaning and maintenance more convenient.

Safety Features:

- • Safety measures, such as explosion vents and pressure relief systems, are incorporated to ensure safe operation.

Fluid bed dryer machines are versatile and efficient, making them widely used in industries where controlled and uniform drying is crucial for product quality. Their ability to handle a variety of materials and provide precise control over the drying process makes them a valuable asset in various manufacturing processes